Not what you may think, but when it comes to lathes, it's certainly a plus. A big lathe can quite comfortably make small parts, but making big parts on a (comparatively) small lathe takes at the very least some ingenuity.

So what did I get? I honestly didn't know what I bought until I had it home and did some research on the internet and had some help from Tony. Turns out this lathe is a rebadged Coronet PLN-5, named a "Rhino Precision" originally made for the American market in the 1960ies and 1970ies. Quite honestly, unlike what you might expect from the afore mentioned facts, it looks quite well built. At the very least, she's a lady with quite a bit of gravity to her.

That first picture, due to lack of comparison, doesn't look too bad...

... but that old Volvo isn't exactly a small car and neither was the trailer.

As such only very few pictures were taken from the actual offloading process. (To be honest, just one.) The engine hoist was making some very unhappy noises and I reduced the amount of working wheels on one of my trolley, when trying to get the lathe into the workshop.

The second question, when buying old machinery, once you solved the classic "how the f*ck am I supposed to get this into the shop"-question, is did I get a bargain or a genuine high-quality... turd.

One of the reasons this lathe was within budget was the fact that it has spent the last 40 to 50 years on a farm and covered in a mix of dust and rust.

When I first saw the lathe, I moved the apron a bit and bare metal became visible, so after three days of marinating the lathe with diesel and a good two hours of scrubbing she's nowhere near pristine, but the bed and all the ways are clean again.

As that came out quite respectable, the next steps will be to get stuck into the electrical side of things, swap out the motor and belts and install a new switch and I guess then it's well about time to find out what the old girl can do.

Thursday 27 September 2018

Friday 21 September 2018

Farewell old friend or how to load a lathe into a van

I've mentioned it before, but today it has become reality. My old Matra MDR2 has made room for its successor.

The following pictures are both a farewell and may serve someone as a bit of helpful advice on how to load a (larger) lathe.

So what's the new one, because surely I have a new toy to play with? Well yes, you're right. Stay tuned. The new old girl will be picked up on Sunday.

The following pictures are both a farewell and may serve someone as a bit of helpful advice on how to load a (larger) lathe.

So what's the new one, because surely I have a new toy to play with? Well yes, you're right. Stay tuned. The new old girl will be picked up on Sunday.

Sunday 16 September 2018

Everyday TR1 - new TM38 carbs (part 2)

Those who know me personally, know that I am allergic to various things: I am allergic to stock (as I assume it can be improved on, once you know what you actually want), I am allergic to trailer queens and showbikes (as I am absolutely convinced that bikes are built to be ridden) and I am absolutely and totally allergic to any mods that decrease usability with the given scope of a bike. Choke knobs that are not (easily) reachable from a sitting position are exactly such a case.

Drumroll, bring on cable chokes – and while we're at install some new inlet rubbers.

As even my local bicycle shop charges somewhat questionable prices for nipples, I bought some brass roundstock and made my own.

Then it was "just" a matter of determining the correct lengths and solder them on.

Handy trick for soldering cables: Gently clamp them in a vise, adjust to the correct height and then solder them. This way they can't move and you don't burn your fingers. And always tin up the cable as a first step.

As I have the throttle-cable splitter on the right, I've put the choke-cable splitter on the left. Cable routing turned out a lot easier than I initially thought. (Read that as feared.)

That sees the choke-cables installed. I didn't synchronize them in any way, just made sure that the cables where the same length within the accuracy of measuring tools available, mainly because I only use chokes "full throttle" and then shut them off, so slightly differences should be neglible. Syncing the carbs themselves is an entirely different matter.

Drumroll, bring on cable chokes – and while we're at install some new inlet rubbers.

As even my local bicycle shop charges somewhat questionable prices for nipples, I bought some brass roundstock and made my own.

Then it was "just" a matter of determining the correct lengths and solder them on.

Handy trick for soldering cables: Gently clamp them in a vise, adjust to the correct height and then solder them. This way they can't move and you don't burn your fingers. And always tin up the cable as a first step.

As I have the throttle-cable splitter on the right, I've put the choke-cable splitter on the left. Cable routing turned out a lot easier than I initially thought. (Read that as feared.)

That sees the choke-cables installed. I didn't synchronize them in any way, just made sure that the cables where the same length within the accuracy of measuring tools available, mainly because I only use chokes "full throttle" and then shut them off, so slightly differences should be neglible. Syncing the carbs themselves is an entirely different matter.

Sunday 2 September 2018

Everyday TR1 - new TM38 carbs

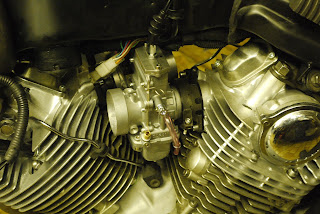

And one day everything is working fine and going smooth. And you get bored. And you strife for improvement. Now even though I have a set of perfectly good Mikuni VM38-9s, I have had a set of TM38-85 sitting on the shelf for way too long.

But first start with a problem aka. oil-leak. Admittedly I had already bought some aluminium roundstock to repair the lower valve-cover thread. Turns out, those heads leak substantially less, when tightened up properly.

The stock jetting with #22.5 pilots and #230 mains is "a tad" on the rich side, a more conservative #20, #190 was chosen for a first start.

Interestingly the rear of the carb is tapped for a air-jet, but the port is run open. As the parts out of the VM38s will fit, I might give those a shot (6DP4-needle and 0.5 air-jet instead of the stock 6FJ4).

The slide assembly is relatively straight forward, the paper gasket got greased up so it won't stick to the cover or carb body.

The throttle cable holder is vastly different and looks a bit like an afterthought. Those M3x10 screws will have to be swapped out for allen bolts as I foresee them to seize in the aluminium slide in the long run. With that being said, a bit of copper-slip should prevent that for now.

The 51-6506 2in1 throttle cables (available from various XS650 shops), are a bit too long, so shortening by about 10-15mm is due in the long(-er) run or you end up with lots of slop on the throttle-grip. A bit of decent allen-bolt hardware should make maintenance a lot easier.

In order to be able to oil the cable from the top, a bit of shrinkwrap seals the adjuster against the cable.

The cable is too long by about 10 to 15mm, so at the very least the bit from the junction box to the throttle grip has to be shortened. Once I get to sync'ing the carbs, I'll probably have to shorten those as well.

The benefit of the TM38-86 is their 47mm outer diameter on the engine side, which makes them a straight fit in the stock inlet rubbers.

Fuel line routing is dead simple, but squeezing a filter in there might present some challenges as there's really not that much space.

Bit of hose-clamp-magic as I seem to have run out of good quality neoprene fuel hose and the normal stuff gets mushy within days, with the fuel we have available overhere.

So what's the first verdict: Jetting will take some effort. Overall the length is very similar to the old VM38s due to the longer inlet rubbers. The sync plugs on the stock rubbers are a heaven's sent for getting the carbs dialed in and there's once more a lot to learn. First step will be to shorten the cables to reasonable lengths and then play around with various air-jets as the mid-range is running very lean. Mains are too big, which is weird as it's the same size that works with the VM38s, but maybe this is due to the synchronization not being what it is on the other carbs.

But first start with a problem aka. oil-leak. Admittedly I had already bought some aluminium roundstock to repair the lower valve-cover thread. Turns out, those heads leak substantially less, when tightened up properly.

The stock jetting with #22.5 pilots and #230 mains is "a tad" on the rich side, a more conservative #20, #190 was chosen for a first start.

Interestingly the rear of the carb is tapped for a air-jet, but the port is run open. As the parts out of the VM38s will fit, I might give those a shot (6DP4-needle and 0.5 air-jet instead of the stock 6FJ4).

The slide assembly is relatively straight forward, the paper gasket got greased up so it won't stick to the cover or carb body.

The throttle cable holder is vastly different and looks a bit like an afterthought. Those M3x10 screws will have to be swapped out for allen bolts as I foresee them to seize in the aluminium slide in the long run. With that being said, a bit of copper-slip should prevent that for now.

The 51-6506 2in1 throttle cables (available from various XS650 shops), are a bit too long, so shortening by about 10-15mm is due in the long(-er) run or you end up with lots of slop on the throttle-grip. A bit of decent allen-bolt hardware should make maintenance a lot easier.

In order to be able to oil the cable from the top, a bit of shrinkwrap seals the adjuster against the cable.

The cable is too long by about 10 to 15mm, so at the very least the bit from the junction box to the throttle grip has to be shortened. Once I get to sync'ing the carbs, I'll probably have to shorten those as well.

The benefit of the TM38-86 is their 47mm outer diameter on the engine side, which makes them a straight fit in the stock inlet rubbers.

Fuel line routing is dead simple, but squeezing a filter in there might present some challenges as there's really not that much space.

Bit of hose-clamp-magic as I seem to have run out of good quality neoprene fuel hose and the normal stuff gets mushy within days, with the fuel we have available overhere.

So what's the first verdict: Jetting will take some effort. Overall the length is very similar to the old VM38s due to the longer inlet rubbers. The sync plugs on the stock rubbers are a heaven's sent for getting the carbs dialed in and there's once more a lot to learn. First step will be to shorten the cables to reasonable lengths and then play around with various air-jets as the mid-range is running very lean. Mains are too big, which is weird as it's the same size that works with the VM38s, but maybe this is due to the synchronization not being what it is on the other carbs.

Subscribe to:

Posts (Atom)