Shout out to my man Big J, but this old girl has come back a third time from the dead. Now, I hear you say, hold on a sec, didn't you just do this a couple of months ago. Yup, perfectly right, but when you outsource work to professionals, it may end up coming back to bite you.

Let's recap, after installing a nice and shiny new piston late last year, the sounds emitted from the old Dre-XT-Stueck, after one particularly spirited break in ride and an attempt to find out how she'll perform in higher gears *ahem*, changed to this slightly more agricultural soundtrack.

Now frankly I wasn't quite impressed with the overall performance and I wanted a 1VJ-head because of the bigger valves anyway, so I got myself a dirty but otherwise sound 1VJ head because of its 37/32mm valves. (Each being 1mm larger diameter than what the early XT600s came with from stock.)

Couldn't leave those ports all stock, could I? Just a little touchup to remove

an unnecessary step on both the inlets and exhausts. And yes, the valve seats

needed quite some work to be nice and shiny again.

Pretty much par for the course, new Viton valve stem seals and 4 new valves as the ends were a bit hammered.

But first, let's pull the engine out and dig into it to find out what made

those forging-hammer-like sounds in the first place. Head's looking good, which makes me a bit happy as there's a "non-stock"

camshaft you see here.

Piston is a bit more oily than I'd like, maybe I was a bit generous with the

oil, when installing it?

Oh oh.

Oh F*ck.

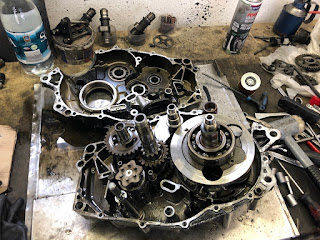

My professional verdict: "It's dead, Jim." Somehow I suspected as much and as such I had decided to dig into the bottom end beforehand as I had a newer version of the oil-pump, with 50 percent wider oil-pump gears from a 1VJ. Unfortunately I couldn't get hold of the final 3AJ-version, which would have even wider gears, but given the fact that the bits in the head were properly lubricated this should do for now. Either way I wanted to have a look at the gearbox (5th gear is a bit of a weak spot on these) and the return-oilpump's pickup, it was splittin' the cases o' clock.

Getting the rotor off on the old XT600s is a proper pain.

Someone has been in there before me - not sure if this is a good or a bad sign, it is a sign nonetheless.

Spatula-origami - the cases split a bit, but I couldn't get them apart. For

some reason the front dowel was well and truly rusted .

Now that doesn't look too bad, if I am honest.

So there was some mayhem going down before I was in here. Also the lid broke

off, it's not actually meant to come apart.

Judging by the chunks in the pickup-mesh and the fact that I have some like

new gears in the gearbox, I'd say last time the gearbox failed.

Tig'ed the cover back on after cleaning.

Quick detour, had to steal the 6004-bearing from the gearbox-output-shaft from

another set of engine cases, as mine was running "a bit rough".

Which as you can tell by the delightful change in scenery has taken place in my dad's kitchen (THANKS DAD) as he has got a nice oven and a freezer, which makes the whole swapping the bearing job and absolute breeze, i.e. put the case-half in the oven and the bearing in the freezer. Have a coffee with dad and when smoke comes from the oven, put the case on an old chopping board and just let the bearing drop in.

Let the whole lot cool down and then go back to the workshop and assemble the whole lot. Note(s): There's dots that have to be aligned on the split gearshift-mechanism.

And the same goes for the balancer-shaft. (Which got me thinking, as I have a

rather rusty and spare balancer shaft, what if one were to remove the

counter-weight? Would it vibrate its guts out, would it rev quicker? Another

time... remember this is supposed to be my cheap and sensible backup daily

hack.)

Now let's have a look at the little gem I treated myself to. A 96mm Wössner

piston, which I was able to pick up for a very decent price in a sale. (I

gambled a bit on this one, hoping that I would be able to save the

cylinder...) Turns out, the piston is, as specified, 95.93mm in diameter. I

was hoping that they would be as generous with dimensions as Wisecoe is and it

would end up slightly more on the upper end of the threshold, giving me a bit

more wiggle-room.

And now here comes the reason the Wiseco seized in the bore: At the top we

have an unhealthy 0.12mm piston to wall clearance. (Wearlimit is 0.1mm over

nominal bore or 0.17mm piston to wall-clearance.) Which is not something that

makes me very happy, but the bigger issue is that it tapered down to 0.05mm,

when I specified the clearance to be 0.085mm for the rebore. Resulting in a

lot of extra friction at the bottom end (causing heat) and then the heat from

the increased compression at the top.

Only thing I could actually do was to hone out the taper and get it to an

uniform 0.12mm clearance.

Next up: Piston rings - recommended clearance is 0.30 to 0.45mm on both

rings. The second ring was somewhere between 0.30 and 0.35mm (as close as I

could determine it with feeler gauges), but I prefer to have the top-ring as

it gets all the heat from the combustion cycle to be on the upper end of the

range as it will expand more and this reduces unnecessary friction.

Ring gaps were at 0.15 and a lot of filing, testing and filing again had to be

done.

Rinse and repeat.

Because curiosity killed the cat and tight squishbands make engines run cool, keep detonation in check and make more power, I just had to try fitting the cylinder without a basegasket. (Tightens the squishband by about 0.50mm.)

But vernier says no. You'd at least want 0.80 to 0.90mm of clearance on a

rollerbearing crank to have enough room for bearing play, conrod stretch etc.

So take the cylinder off again, put a well greased base gasket on and assemble it.

Make sure the piston is REALLY at TDC. (Little dot on the crank and little

arrow on the case are aligned.)

And then you usually end up with a choice: Slightly retarded

... or slightly advanced camshaft. Somehow it just doesn't seem to fit

perfect.

Slightly advanced is the correct answer, because the camchain will stretch and thus slowly retard anyway. (One of the main reasons, why older engines often feel a bit sluggish.) Funnily enough, you will only encounter this to the extent shown above with a brand-new camchain. Once it has stretched a bit, it will either look terribly retarded or ever so slightly advanced.

Just to finish it off, the head one missing and one bent exhaust stud, so this had to be addressed.

Top half of the cylinder head on and the engine's actually looking almost done.

Clutch cover needed a new oil-return valve as it was leaking a little bit and to be fair, I had it sitting on the shelf for quite a while and it's one of those costs-next-to-nothing-but-your-time fixes. (It's just a seal, a ball and a spring.)

Put the engine in with the help of my dad and called it a (long) day.

Only to be greeted with this the next morning. Turns out, it does help to tighten the oil-drain plug tightly. Also the kickstart would jam and the clutch-adjustment was way off from what it was before.

The kickstart-ratchet issue was easy, just wind it up like a clockwork and preload it and it will only fit in there one way. The clutch is a bit more tricky - usually if you have "special" clutch disks, there's only one of them and usually it is the very first one. Well not so much with XT600s, there the first and last disk have got a bigger inner diameter.

Also if you align the dot and arrow, that's the only way the teeth mesh correctly.

The adjuster in the middle sets how far the clutch lever is angled and you'd want to set it up, so it fully disengages the clutch at a bit over 90 degrees for the lightest clutch pull.

Check the oil (again) and give her 2-3 good kicks and the old girl is back in action.

Quick check and the return-oilpump is feeding back nicely. (As I swapped the oil-pump I was a bit anxious whether it would work decently, which obviously it does.)

Well about time to have some fun with the old girl... except at some point the front tube must have shifted a little bit on the rim and the valve was on a very jaunty angle, resulting in potentially ripping out of the tube, so that was fixed as well.

Guess a testride is due?