Some people tend to make create problems for themselves. Take a perfectly good running motorcycle, a bit sluggish perhaps, but good running nonetheless. I confess, I am one of those people. Please don't get me wrong, there's nothing fundamentally wrong with that 95.25 setup, aside from maybe the fact that after a 620cc high-comp bigbore setup the old girl was feeeling "a tad" lame.

That being said, some may recall I originally got myself a beautiful Wiseco 97mm piston with stupid high compression. (IIRC 11.5:1 - in the picture below it's the one with the carbon buildup.)

The other one is a Mahle out of a KTM LC4 620, but the more modern 640 is the same as they only increased the stroke. Also, this puppy is a whopping 101mm bore-size, which incidentially is exactly the same as on a XT660... bad ideas? Me? Nah... For those going down that rabbit hole, the SuperComp and SXC models ran a forged Mahle, the standard models a cast piston. Compression ratios are the same on both.

After maybe giving one of you fellas some bad ideas, back to the main topic. As some may recall, I run a XT600Z (1VJ) carb on my XT. Which was pretty good on the first bigbore, but a bit of a pain with the stock piston. At the time of writing I am already contemplating, when to find some time to put it back in, at least for the initial break-in period. BUT, as luck would have it, I got my dirty paws on another XT600 carb, but this time the most desirable one, by the opinion of many folks I have spoken to, a 2KF version.

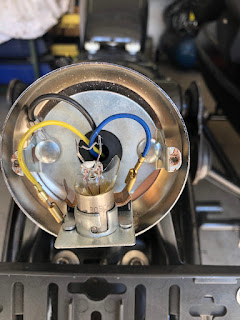

Up to this point I was convinced that the differences were only in the jetting and base setup, but it turns out that for example the slide in the primary carb is also slightly different (you can see a port in the back, not present in the 1VJ-carb on the left).

So I installed the 2KF and... well, things didn't quite go swimmingly.

It turned out that a big flake of something was stuck under the needle as somebody had removed the screen over the float valve. Luckily I had a semi-broken carb at my disposal and could take the screen from that one.

I merrily went about my usual business with the old girl and life was fairly good until the main fuse mechanically broke and I lost all my ancilliaries. (Yay for battery-less ignitions!) Then again, why it took me nearly a decade to come up with the clever idea to drill a hole into the top of the (former) battery tray to route the fuse down there... not my brightest moment.

... and then a few days later a parcel from my favourite (used & new) XT and SR parts supplier arrived and was expedited in style to the workshop.

Said box contained: a slightly used JE 98mm piston, with an not overly excessive 10.5:1 dome and a freshly bored and honed cylinder to put it in.

Friday morning (9:22): Dre-XT-Stück is ready to be the center of attraction for the better part of the day.

9:28: The old girl strips quicker than an exotic dancer confronted with hundred dollar bills.

9:35: Quick chat with grandma and the other old girl is on the stand and the engine is loose.

Put the piston on TDC to check my timing marks

9:45: Engine is stripped down far enough only to miss having the pistons swapped out and start reassembly. (Narrator's voice from the off: It was at this point, when he wondered if he might have worked on those XT600s a bit too often lately.)

Quick side-by-side of the two pistons - the size difference in real life is much more notable, when you have both in front of you.

"Couple of rags" to prevent dropping the clip into the engine. Something which has never happened to me (yet), but has been frightening me ever since.

Shortly past 10:00: Cylinder going back on.

11:15 (and quite a few rude words): another one of those M6 threads that hold the camshaft down have failed and needed a timesert.

11:45 (almost) Ready to roll.

Whilst I was at it, I quickly experimented with an XS650SE fuel tank - sits too high, but in general the oldskool Scrambler look could be a nice alternative for those days, when large tank and panniers is not the way to go.

A quick first rideout was had, which revealed:

- carb desperately needs a rejet as that 633 is pumping a lot more air through than the almost stock engine

- this is going to be a good un'... even though it was running lean there was a lot more oomph down low already.