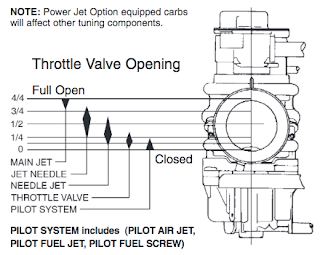

At first, let's flog a dead horse by having a look at the following schematic:

|

| Source: Mikuni Corp, 2012 |

Let's just simply follow the carb slide through a usual day at work and identify the problems I encountered. (and most likely you did too, because quite frankly otherwise you probably wouldn't be reading this!)

For coldstart we obviously need to pull the choke knob and enrich the mixture and then run the bike (mainly) on the pilot jet and the additional choke jet. There's mainly two things aside from the choke affecting the mixture at this point and that's the pilot jet and the slide cutout. (called throttle valve in the schematic above) Now it should be obvious that the smaller the slide cutout the less air goes through at the same height of the slide, also the slide cutout basically determines how steep the curve rises that determines how much air gets to the engine at very low slide opening. This (within the limits of the engine) determines how "snappy" an engine will feel to the user. Additionally a smaller slide cutout will help to keep things more moderate and make jetting the pilot easier.

Real world example: a VM38-9 has got 2.5mm slide cut-out and a TM38-86 has got 4mm. The jetting on a Yamaha XV1000/1100 engine is pretty close in both instances, but trust me, a TM38 with the bigger slide cutout will feel a lot snappier.

Pitfalls (or also why you shouldn't start jetting from the bottom up): For rather obvious reasons it would be very tempting to start jetting from the bottom up, because then even if everything else fails, you at least would end up with a decent idle. And here comes the catch: as I pointed out before the schematic above only applies, if everything is working perfectly and even then the whole system is rather dynamic, meaning if your jetting is off, it simply doesn't add up. Assuming that for example your mainjet is dramatically oversized, it will overlay and obscure incorrect (lean) jetting in other areas. The art of jetting carbs is knowing some recipes, which usually work and then apply some common sense, e.g. if you run a #300 main-jet and the smallest pilot jet IIRC a #12.5 and your bike is still running so rich it will fire up without using the choke, there is a strong reason to believe that maybe your pilot jet is not the reason. Let's assume you get past this point and your jetting is somewhere in the vicinity of #20 pilot and a #185 main-jet. (Seems to be roughly the golden numbers for a Yamaha XV with a TM38, when sucking through the frame with a correctly sized airfilter and a free flowing exhaust.) Yet still it seems to idle weirdly when cold and once hot it will race to stupidly high rpm or even worse, when really hot will fall on its face again and not idle properly. The next thing is to look at the slide height: One of the standard pitfalls to compensate an overrich pilot is to raise the slide until it will idle just fine. This will then result in climbing idle for a bit only to have the bike lose idle once it has warmed through.

Next let's look at mid throttle openings. As stated before when the slide opens, the slide cutout is the main determining factor for how quickly the amount of air increases that gets into the engine. In parallel, as can be seen in the picture above, the carb needle isn't a straight control rod either, but is tapered. And now this is where things get tricky, because there's a lot of things that can be adjusted at the same time and even though on paper the results in AFR will be comparable the consistency of maintaining said target AFR. This brings us to the resulting question: Which options are there and what does what?

- The needle taper controls the steepness of the curve (progression). A thinner needle will mean a richer initial mixture and depending on how steep the needle is, it will mean also affect how rich the mixture is at max. slide opening and thus affect the main-jet.

- The clip position will set up where the starting point on the taper is. This can be very helpful, if you run a needle with a relatively flat taper, but almost impossible to use with a needle with a steep taper as even small increases dramatically change the effective diameter of the needle in the needle jet. (And that's completely ignoring the effects of worn carburettor needles, which may have a ridge worn into them at one point...) It has to be noted that some carbs come with needle shims to somewhat compensate for this, when quite literally the setting changes that can be achieved with the clips are too coarse.

- Lastly the needle jet, this is the only linear modifier in this equation. A bigger needle jet will quite simply increase the amount of fuel all the way from bottom to top.

|

| Source: Mikuni Corp, 2012 |

The last stop in our journey is full throttle. Even though this is the point, where the most can go wrong, it's also the easiest to jet. Following some gutt-feeling and experience one usually starts this "a tad" richer than is expected to be right and once the bike has warmed up, literally just hammers the proverbial snot out of the engine by doing full throttle pulls. Installing smaller mainjets until the performance can be felt to go down, pinging occurs or the oil-temp goes through the roof. (Usually it''s a combination of all three, but with a bit of careful testing one can keep this within safe limits at the very first point of the list.) With the orifice of a main jet being so vastly bigger than all of the other jets that's also why you usuall start there and try to get the mains right for a start as mistakes there will trickle down all the way and even affect pilot jetting.

So where does this post come from: Basically I was trying to organize my thoughts and trying to work out, what exactly needs to be tackled to get the TM38 carbs on my Everyday TR1 working perfectly. The situation is as follows: Bike idles fine when cold and up to a certain temperature, even though the RPMs vary a bit, once really hot (as in above 110 degrees C of oiltemperature) it completely falls on its face and will only idle when the slide is lifted a bit, clearly indicating an over-rich pilot. At the same time when up to temperature, there will be a certain amount of pinging at low (1/4 to 1/2) throttle opening indicating a relatively lean mixture at that and the mainjet is quite substantially larger (#185) than on my old VM38-9 carbs (#165), even though the effect is less felt at wider throttle openings.

Following the long winded text from above everything is pointing towards a somewhat too lean needle and as the problem isn't really linear (especially as the main-jet is actually about right, keeping the engine oil-cool, no detonation, power seems about right and the plugs aren't fouling), it all points towards the needle I am using isn't perfectly right for the application. As I actually ordered the new needles before finding the chart above, I now have a set of 6FJ40 needles to play around with. (Once the snow and salt are gone, some serious testing will commence!) I expect to finally be able to decrease the size of the pilot by one size and go back to a #20 and overall experience lower engine-oil-temps as the bike isn't running on a lean midrange.

Hey Greg, Great article! I am still working on the jetting on my XV700. The one I almost gave up on until you suggested I was too fat on the mains, which I was way too fat. Here is where I am at on mine. It runs great at all RPM's I get only slight idle variation when real warm. I still do have to change the rear spark plug periodically because it will foul if left idle too much. Smooth as silk all the way past 7000 and plugs are that beautiful brown color. I do have to use choke when cold. I was thinking to try new slides but they are expensive or maybe a Q0 needle jet in the rear. I am going to let it ride like this this summer but I am sure it will work on me and I will have to try it. Currently here is where mine are set at. I write it down as I go and how they perform. I am really getting fast at carb removal, install, and syncing. Mains are 160 front, 150 rear, #10 pilot (yep it runs and works), needles all the way up, Q2 needle jets, air screws are out 1 1/4 turns. I can't tell you how much you help XV owners with your comments and knowledge. It is very much appreciated and I thank you. I have also attached some info that may help some owners. It's a little tuning tidbit I found on the Mikuni site for dialing in the main jets on a HSR42 but the same principles apply to the TM's. Thanks again, Kasey

ReplyDeleteROLL-OFF:

The Roll-Off technique is the quickest and is almost as accurate as the Roll-On method. First, one gets the engine warm on the way to a safe roadway. If there is room, use fourth gear as this allows more time to assess the result.

Now, get the engine rpm high enough that it is on the cam and in its power band. This may need to be as high as 4000 rpm with some cam choices. Apply full throttle. Let the engine accelerate for a couple of seconds until it has settled in and is pulling hard. Quickly roll the throttle off to about the 7/8ths position. When you do this, the mixture richens slightly for a second or so.

If the engine gains power as you roll the throttle off, then the main jet is too small and you need to fit a larger one.

If the engine staggers slightly or has a hard hesitation, then the main jet is too large and you need to fit a smaller one.

Thx for the kind words. Then I have to admit, this isn't going to be the only article in the series, if people actually want to read all this, then I am more than glad to put down a bit more of what I know. (Trying to sneak round the word knowledge like a ninja ;-) )

DeleteOne of the next posts in this series would have been on jetting mistakes. What you are actually doing (and I suppose your gas mileage will sort of prove it) is running the engine like on a Lectron carb, only via the needle.

If you have to swap one of the spark plugs every now and then, then you either have a knackered coil (happens) or your jetting is off. Guess, what I am hinting at. Try setting everything up, so you can run the needle at more or less the middle notch. Most likely you will end up with a slightly bigger mainjet and a substantially bigger pilot. (I checked my notes currently running a 22.5, but with a slightly too lean needle, so I plan to go back to 20 myself, also this will help with gas-mileage a bit, as the pilot is always in use.)

Oh and from personal experience: unless you have a really terrible exhaust on your bike, e.g. all stock TR1 or XV920R with all the baffles intact, don't bother with jetting front and rear differently.

Hey Greg fantastic article. I have a tr1 with vm36 on it but are going to swap out to TM 38s. Custom free flow pipe with equal length headers and running ramair pod filters. What jetting jet needle etc would you recommend to start with. Here's a link to pics of the bike. https://thebikeshed.cc/pacific-motorcycle-co-xv1000/ Cheers Kev

ReplyDeleteHey, now that's a nice build of yours. Not sure about the exhaust, but that could become a bit of a bottle neck, unless you go full "I-hate-my-neighbours"-mode. ;-)

DeleteSo far I've run mine with the stock 6FJ41 needle, #20, #175 and the air-screw only 1.25 turns out. I have recently bought a set of 6FJ40ies and as you will see in my next post, they are much richer, so I think they should be the ticket and also allow me to run #17.5 pilots.