With fitting those welded up heads onto my TR1, I have sort of opened a can of worms in my head. And it is a large and ugly one. As I pointed out 4 years ago the wedge design I chose was the most simple I could think of and also the most easy one to manufacture. The designs appears to be sound, so why change it? In short, because I was inspired by a much more complex shape and I secretly hope that amongst my readers there is someone, who has sufficiently got his feet wet with cylinder head combustion chamber design for two-valve designs.

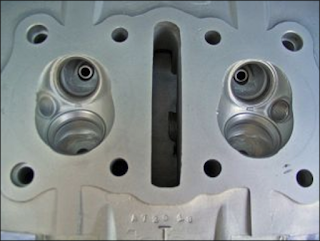

My Problem, I was inspired by the combustion chamber of the XS400 and XS850 engines, which both run an 8-shaped combustion chamber.

Spotted the difference?

On an XS400 the combustion chamber gets narrower towards the exhaust valve, whereas on the XS850 it opens up. As a result one can make a fitting case and argumentation for each design:

- Narrowing the combustion chamber towards the exhaust valve creates a high-pressure zone around the exhaust valve, leading to a much higher pressure difference once the exhaust valve opens and a faster evacuation of the exhaust gas and thus potentially a higher gas velocity in the exhaust. Also as the gas is experiencing a progressive increase in the backpressure it is likely that it will "pile up" in the center of the combustion chamber and stay under the spark plug longer thus making it a more efficient burn perhaps?

- Widening the combustion chamber towards the exhaust valve makes use of the inertia the gas already has when it is sucked in and biases the gas to move more towards the exhaust valve and flow through the chamber faster. All of this may happen for the price of a slightly less efficient burn in the chamber.

What has got me so confused with those two examples above are that even though one is a twin and the other a triple, they have roughly the same max. rpm and the powerband is more or less in the same rpm-range as well. Also both engines have been designed at roughly the same time, the wedge head on the late XS750/850 maybe came a bit later, but for the sake of this argument it is safe to assume that they were designed at roughly the same time. The specs of both engines aren't exactly enlightening to me either:

- XS400 - bore x stroke 69 x 52.4mm, compression ratio 9.2:1, max. output 27kW@8100rpm and max. torque 33NM@8000rpm

- XS850 - bore x stroke 71.5 x 68.6mm, compression ratio 9.2:1, max. output 57.7kW@8500 rpm and max. torque 70NM@75000 rpm

As one can't simply normalize the results on a per cylinder basis as the triple has got an extra cylinder (duh) and thus provides 50 percent more impulses per crank revolution, at the expense of only 33 percent more friction losses, the only obvious difference lies in the stroke of the two engines. (I am well aware that this last paragraph is overly simplified and those numbers are definitely not going to hold up to scientific scrutineering, but I am convinced the general direction is correct.)

Therefore I assume it is the right thing to do to go with a combustion chamber that widens around the exhaust valve. Especially as the stroke on my XV1100 crank is closer to the XS850 than the XS400.

After this long winded explanation let's get to the status quo - a wedge perpendicular to the camshafts rotational axis or more easy to imagine along the main axis of the bike.

The most easy fix (at least on a new head) would be to angle the wedge to create a low(er) pressure area around the exhaust valve. The downside to this idea is undoubtedly an obstruction around the inlet valve, which may obstruct the airflow around the inlet valve.

On the existing heads angling the wedge is very likely only very hard to achieve without having to deck the head once more and there's honestly not that much meat left, before one would have to cut deeper valve pockets into the piston. As such mimicking the already existing taper around the exhaust valve could help with both reducing valve shrouding (if one were to move the wedge much further in) and create a lower-pressure area around the exhaust valve.

Assuming that the new wedge runs right through the middle of the sparkplug-thread, in order to unshroud the valves an 8-shape might be the way forward for those heads. Obviously this would mean to either sink the spark plug seat in further into the head's casting and use longer-threaded sparkplugs with some elaborate milling-work.

I am totally aware that the way the circles are drawn around the valves they are exactly opposite of what I described before as my strategy - please see them more as a sketch and the basis for discussion.

In reality this post neither doesn't supply a conclusive answer nor does it attempt to do so. I hope for it to be a conversation starter. Especially as most of the two-valve head designs that I have encountered are traditional hemispherical combustion chambers (thinking of all the big fours aside from the XS1100, which goes with the 850 design) and the same goes for the old SR500/XT500 engines. So if you have some to share that would really be great and could help a lot in deciding how to go ahead with this project.

No comments:

Post a Comment