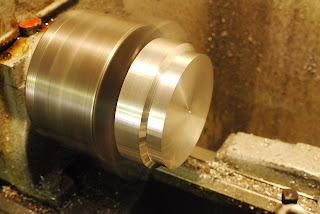

Before we get into the matter at hand, let me show you a result. Some people asked me, what kind of finish could be achieved with such a big and heavy flycutter on such a small and puny mill. A pretty shiny one, if I may say so.

What was needed next was a means to hold the cylinder in the lathe. (More on that later!) This was finally the time to REALLY chase the accuracy of my lathe. I ended up with two plugs that would almost seal the bore and would only go off with a slight. *plopp*

Looks good doesn't it and it over the lathe's bed. Well, not so fast... as it doesn't clear the outriggers of my support.

So what you will see in the next installments, is on the one hand establishing the missing base data regarding the squish-height, which in turn defines the amount of material to be removed from the cylinder foot and on the other hand tooling up even further to get my rotary table working with the chuck I have for it.

No comments:

Post a Comment