Alright, it's exam time and what would be better suited to help me with learning for my exams than establishing some base data on the engine I have been building for literally FOREVER.

But first I had to retap the cases for the starter. With the aid of a little jig I made in the lathe it was pretty easy to hit dead-center, drill it and tap it.

Also in this picture: The oil-pressure-switch. It's the standard M10x1.00-threaded (opening at 0.9 bar) unit as used on a plethora of Volkswagens. Be aware there's two of them, blue and grey ones, one being a closer and one being an opener.

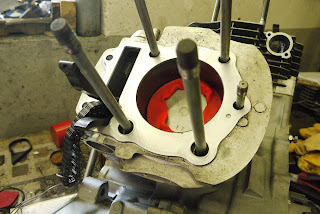

Now with that out of the way it was well about time to put the engine onto the other workbench and get the measuring clay aka. kid's plastilin out.

Install the headgasket, put on the head, turn the piston back from TDC and then give it a full revolution.

If the amount of clay was sufficient, you wil have an impression of the combustion chamber on the clay.

Cut back the clay to the areas you really want to measure and fire away with the vernier caliper. In my case I ended up with 1.64mm as the tightest spot. I aim for just shy of 1.00mm, so that means this cylinder has to be shortened by 0.65mm. You then repeat the same procedure on the other cylinder.

The same method can also be used to inspect the piston-to-valve clearance, which can become interesting when you either run cams with more lift or bigger valves or a combination of both. It's the classic case of knowing what you can get away with. The next post in this series will give you an insight, why you haven't heard from me in quite a while, i.e. stories of carnage. I have a few ideas on how to rectify the situation, but I haven't fully come to a decision as of yet.

Shortening the cylinder will make the cam chain require more tension - more than the stock can deliver? - and also retard cam timing. Do you plan to degree the cams as well?

ReplyDeleteLuckily it's not like I am taking several mm off the base of the cylinder, so the chain shouldn't be an issue (it's a new camchain anyway), with regards to adjustable camshaft sprockets, I have been playing around with that idea. A bit of retard will give me more torque and just cut some of the max. horsepower. So yes, ultimately I will have to tackle this, but it should be fine for now.

DeleteSounds good!

ReplyDelete