August, 30th is registration day for the XS Triple Sidecar. And even though the old girl had come a long way there was still LOTS to do. Firstly as the preemptive inspective brought up, I had to build a steering damper. As much as a standard motorcycle steering damper would work they are rather costly and as I have a sidecar strut to affix it to, there's easier ways in getting the job done with a car-steering damper. The one used on here is for a Mercedes W124 and is a whopping 30 Euros.

Doesn't look like much, but was the better part of a day's work...

For some bizarre reason the brake pads were completely oily, greasy and mucky, even though the forks are nicely dry and leak free, so I rummaged in my parts bins and found this set of old sintered Dunlopad pads, which probably came out of my very first TR1.

Another thing that had to be tackled: The stock speedo wasn't working (and when I took it out, it became obvious that the old XS triple must have landed on its at least once and proper hard), so it was replaced by one kindly donated by a friend. (I still have to get in there once more after registration to replace all the lightbulbs with LEDs, but I am not gonna chance it before the registration!)

Another thing that had to be tackled was to enumerate various relevant parts, e.g. the sidecar frame needed a VIN. (If you ever wondered, where the infamous Dnepr Sidecar number 001 went, here it is! 😉)

And here you have it, technically two days of work and you see: not much has changed.

Btw.: When this post comes out, the inspection will have taken place at 10am (CET) the very same day.(And the old girl has passed with flying colours...)

Wednesday, 30 August 2017

Friday, 25 August 2017

Project "pretty one" - digging into the engine and finding...

... not much. Except for a stuck oil-ring and that the two inlet valves have touched the piston and are not bent. Which in my book is enough to explain the quite stunning "I am a two-stroke"-charade of the old XT. 😉

Nothing much to see and find on the very top of the engine. Cam and rockers still look like new, but getting the valve cover can be a bit of a pain, if you forget about that one bolt that sits between the two ears of the head-to-frame-mount.

Once the head was off there wasn't any damage immediately visible. It was quite a bit oily, yes but at first glance all good.

Then I had a look at the piston and was stumped. When putting the engine together last time, the valves must have just touched the piston.

Which was proved after some closer inspection of the two inlet valves.

The standard leakage test revealed marginal leakage after about ten minutes, but nothing that would worry me or indicate a bent valve. After all this engine has done 42,000km so far.

Heaps more annoying: The oil-control-ring is somewhat stuck in its groove and there's also some light scoring on both the piston and cylinder.

Next time I'll brake out the subito and measure both cylinder and piston and see whether we can just sneak in a set of rings and do this on the cheap or whether we should go all in and get the cylinder bored and fit an oversize piston.

Nothing much to see and find on the very top of the engine. Cam and rockers still look like new, but getting the valve cover can be a bit of a pain, if you forget about that one bolt that sits between the two ears of the head-to-frame-mount.

Once the head was off there wasn't any damage immediately visible. It was quite a bit oily, yes but at first glance all good.

Then I had a look at the piston and was stumped. When putting the engine together last time, the valves must have just touched the piston.

Which was proved after some closer inspection of the two inlet valves.

The standard leakage test revealed marginal leakage after about ten minutes, but nothing that would worry me or indicate a bent valve. After all this engine has done 42,000km so far.

Heaps more annoying: The oil-control-ring is somewhat stuck in its groove and there's also some light scoring on both the piston and cylinder.

Next time I'll brake out the subito and measure both cylinder and piston and see whether we can just sneak in a set of rings and do this on the cheap or whether we should go all in and get the cylinder bored and fit an oversize piston.

Wednesday, 23 August 2017

The XS Triple Sidecar - fusebox and breather

One of the things that can really make or brake your experience with a bike is reliable electrics. And one of the most overlooked parts of said electrics are fuse boxes. Old grimey fuse-holders often lead to dramatic drops in overall voltage or even no voltage at all. Cleaning the contacts is a good temporary solution, but when you realise that one of the tabs is actually broken and that's why your headlight is more like a candle in an old lantern there's an issue that has to be addressed.

The amount of space under the seat is "a tad" limited, so a fuse box with side-connectors had to be used.

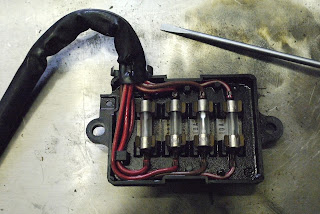

The stock fuse-holder with glass fuses and not one of them being of the right specification...

And that's the new fuse box wired in and boy is that headlight bright now...

The other thing I really had to tackle was the lack of a breather filter. Opinions on these vary, but I am pretty convinced, if it is oiled up properly it will not aid condensation inside the engine. Now of course I couldn't get one (locally) that would fit straight out of the box, so I had to fire up the lathe and make an adaptor:

The red K&N-oil will add at least 10hp. 😉

Last thing missing is the steering damper mount, which you will see in one of the next posts.

The amount of space under the seat is "a tad" limited, so a fuse box with side-connectors had to be used.

The stock fuse-holder with glass fuses and not one of them being of the right specification...

And that's the new fuse box wired in and boy is that headlight bright now...

The other thing I really had to tackle was the lack of a breather filter. Opinions on these vary, but I am pretty convinced, if it is oiled up properly it will not aid condensation inside the engine. Now of course I couldn't get one (locally) that would fit straight out of the box, so I had to fire up the lathe and make an adaptor:

The red K&N-oil will add at least 10hp. 😉

Last thing missing is the steering damper mount, which you will see in one of the next posts.

Friday, 18 August 2017

Project "pretty one" - pulling the engine out and finding the fault on Dre-XT-Stück

Sorry for stuff being a bit jumbled up chronologically, when this post comes out it will actually look back two weeks to when this actually happened, but a lot has happened since and probably even some more will, as I am still head over heels in doing all the legal work to get my sidecar on the road.

With that being said, right after we got the sidecar outside of the workshop my dad asked me, whether we could pull the engine out of "pretty one", so he could attack thirty years of dirt and grime and have the engine on the bench at the same time, so further investigations can take place.

Taking the engine out on a XT 500/600 4 Valve is a pretty straight forward process: There's one mount on the head, a double mount on the front and the swingarm bolt and one bolt below make up the rear mounts.

A small car jack makes things a lot easier and means you could theoretically even do it alone.

And that's the engine out and on the bench for further investigation.

After that we put a rag over the engine and parked the pretty-one somewhat closer to the wall and decided to swap out the stock carb of the Dre-XT-Stück with the one from the "pretty-one", which also mandated swapping around the inlet-rubbers.

And guess what: Nothing. Same issues as before. So it was pretty clear that it wasn't (only) the carburettor that was causing the trouble, but something else. But I did note, that it would pull cleanly for a short while and then stall. So I decided to renew the fuel line and replace it with a longer hose in a sweeping bend.

Let me politely say: F*ck you hose! F*ck you stock carburettor! F*ck you my own hybris for taking a short cut with a short piece of hose and being sure that it would work alright.

With the old Dre-XT-Stück now running like a scalded cat (a bit rich perhaps), we even went as far as to add the missing left side panel (and peel off some of the old stickers!)

With that being said, right after we got the sidecar outside of the workshop my dad asked me, whether we could pull the engine out of "pretty one", so he could attack thirty years of dirt and grime and have the engine on the bench at the same time, so further investigations can take place.

Taking the engine out on a XT 500/600 4 Valve is a pretty straight forward process: There's one mount on the head, a double mount on the front and the swingarm bolt and one bolt below make up the rear mounts.

A small car jack makes things a lot easier and means you could theoretically even do it alone.

And that's the engine out and on the bench for further investigation.

After that we put a rag over the engine and parked the pretty-one somewhat closer to the wall and decided to swap out the stock carb of the Dre-XT-Stück with the one from the "pretty-one", which also mandated swapping around the inlet-rubbers.

And guess what: Nothing. Same issues as before. So it was pretty clear that it wasn't (only) the carburettor that was causing the trouble, but something else. But I did note, that it would pull cleanly for a short while and then stall. So I decided to renew the fuel line and replace it with a longer hose in a sweeping bend.

Let me politely say: F*ck you hose! F*ck you stock carburettor! F*ck you my own hybris for taking a short cut with a short piece of hose and being sure that it would work alright.

With the old Dre-XT-Stück now running like a scalded cat (a bit rich perhaps), we even went as far as to add the missing left side panel (and peel off some of the old stickers!)

Wednesday, 16 August 2017

Building a DB-Killer that actually works

Most of those universal muffler-tip inserts you can buy out there are all nice and good, if you're *JUST* over the legal noise limit. Now my exhaust on the TR1 and on the XS-Triple-Sidecar weren't a bit over the legal noise level, they had to be silenced quite a bit - which meant around 20db on the TR1 and I didn't check on the XS Triple Sidecar, but it was around the same amount.

That being said, the main flaw of most muffler inserts is, that they don't force the exhaust gas around corners and thereby don't reduce the speed of the escaping gas sufficiently. I sought to change that with this relatively simple design.

I used some big washers turned down so I could weld them to the inside of a tube that would go into the slip-joint of the muffler.

Cut two lengths of tubes that would fit inside the center hole of said washer and made a plug on the lathe, which would go between said tubes.

And this was my first prototype. The holes were ground with an angle grinder and relatively large compared to the actually used inserts. But it proved a quite dramatic noise reduction was possible.

So how does it work: The exhaust gases come in through the center hole, escape through the first hole, have to go all the way round to the other side and escape through the bottom hole. All of which results in a massive reduction of gas-velocity and thus less noise.

In order to make the legal side of things easier on me, I decided to weld them in completely to make sure that during the inspection the engineer wouldn't add a line saying something like "removable muffler-insert" to my papers. As that's what the police always checks first overhere.

Another setup I tried before and which (to my surprise) worked better than expected, were these really simple inserts, basically just comprising of a large washer with a 20mm hole. If you're a bit gentle on the throttle the noise levels up to around 3000 - 3500 rpm are nearly the same (you'd have to have both bikes sitting next to each other to really make out a difference), but especially at higher rpms it's lacking dramatically.

All of that being said, the first set of GreasyGreg Exhausts has been entered into the legal paperwork of my bike and it will certainly not be the last.

Oh and if you're worried, don't the actual registration code of my exhausts is quite a bit longer than that... This is only the "model identifier". Pretty posh, eh? 😎

That being said, the main flaw of most muffler inserts is, that they don't force the exhaust gas around corners and thereby don't reduce the speed of the escaping gas sufficiently. I sought to change that with this relatively simple design.

I used some big washers turned down so I could weld them to the inside of a tube that would go into the slip-joint of the muffler.

Cut two lengths of tubes that would fit inside the center hole of said washer and made a plug on the lathe, which would go between said tubes.

And this was my first prototype. The holes were ground with an angle grinder and relatively large compared to the actually used inserts. But it proved a quite dramatic noise reduction was possible.

Without an insert the TR1 was idleing at around 82 to 84db and the amount achieved, with no further damping material (i.e. stainless steel wool pot cleaners) was below 70db. The measurements were taken 1m behind and 1m to the side of the exhaust.

So how does it work: The exhaust gases come in through the center hole, escape through the first hole, have to go all the way round to the other side and escape through the bottom hole. All of which results in a massive reduction of gas-velocity and thus less noise.

In order to make the legal side of things easier on me, I decided to weld them in completely to make sure that during the inspection the engineer wouldn't add a line saying something like "removable muffler-insert" to my papers. As that's what the police always checks first overhere.

Another setup I tried before and which (to my surprise) worked better than expected, were these really simple inserts, basically just comprising of a large washer with a 20mm hole. If you're a bit gentle on the throttle the noise levels up to around 3000 - 3500 rpm are nearly the same (you'd have to have both bikes sitting next to each other to really make out a difference), but especially at higher rpms it's lacking dramatically.

All of that being said, the first set of GreasyGreg Exhausts has been entered into the legal paperwork of my bike and it will certainly not be the last.

Oh and if you're worried, don't the actual registration code of my exhausts is quite a bit longer than that... This is only the "model identifier". Pretty posh, eh? 😎

Saturday, 12 August 2017

Legalize it! (The XS Triple Sidecar and the TR1 that is...)

... not talking about any psycho-active substances. As the regular followers of this blog might have noticed, apparently some of my stuff was getting pretty close to the mythical state of "done". And in fact they have. On Thursday I had set up my appointment with a government engineer to check up on both the Tractor (everyday TR1) and the XS Triple Sidecar. As is custom with such dates, all of a sudden lots of issues and niggles have come out of the woodwork and meant that from Tuesday evening onwards I was burning a lot of the old midnight oil.

On the TR1 the main goal was to finally declare all the mods done to it and finally run it as legal as technically possible. Except for muffling the exhausts (there'll be a separate post on those muffler inserts "db-killers") there was also the issue of mounting the numberplate and rear light at a steeper angle to comply with local law.

I proudly present the world's chunkiest, billet aluminium numberplate mount. Solid enough to lift the whole bike with it. 😏

Now of course the XS Triple Sidecar was the bigger challenge. Firstly the sidecar's suspension had to be set up correctly.

The forks were pushed too far through the yokes, resulting in a rather nervous driving experience.

The front mudguard had to be drilled as it's off an XV750 and the holes didn't line up perfectly resulting in a weirdly high mudguard.

And then there was a little pet-project: I wanted to have the choke control on the bars. Which is quite easily done, if you have a set of TR1 or XV750 handlebar switches, as a stock TR1 has got exactly this lever on the bottom of the left control. The switches are all the same, so you can just swap the casing around as you like, resulting in the Turbo no sporting a clean switch with no choke lever and the XS Triple Sidecar being exactly as awesome as it is.

Of course I also had to install muffler tips on the XS Triple Sidecar and in the long run I'll also install an H-pipe to link the two long rear pipes, because the exhaust pressure is really, really high resulting in the XS nearly being louder than the TR1.

Probably install that H-pipe right somewhere overhere, where the twin pipes are joined into one on each side.

On the TR1 the main goal was to finally declare all the mods done to it and finally run it as legal as technically possible. Except for muffling the exhausts (there'll be a separate post on those muffler inserts "db-killers") there was also the issue of mounting the numberplate and rear light at a steeper angle to comply with local law.

I proudly present the world's chunkiest, billet aluminium numberplate mount. Solid enough to lift the whole bike with it. 😏

And that's the muffler tips in question. Believe me, when I say they work waaaaaay more efficiently than I wanted. (The TR1 is now 7db less noisy than a stock bike. You really have to use the tach to make sure it's running.) But hey, it got me through inspection and the bike's performance hasn't suffered too badly. So in the long run I'll open them out a bit, but other than that... Interestingly enough they also improved the low-end torque quite a bit and helped to smooth out some slight transition issues from pilot jet to needle.

Now of course the XS Triple Sidecar was the bigger challenge. Firstly the sidecar's suspension had to be set up correctly.

The forks were pushed too far through the yokes, resulting in a rather nervous driving experience.

The front mudguard had to be drilled as it's off an XV750 and the holes didn't line up perfectly resulting in a weirdly high mudguard.

And then there was a little pet-project: I wanted to have the choke control on the bars. Which is quite easily done, if you have a set of TR1 or XV750 handlebar switches, as a stock TR1 has got exactly this lever on the bottom of the left control. The switches are all the same, so you can just swap the casing around as you like, resulting in the Turbo no sporting a clean switch with no choke lever and the XS Triple Sidecar being exactly as awesome as it is.

Of course I also had to install muffler tips on the XS Triple Sidecar and in the long run I'll also install an H-pipe to link the two long rear pipes, because the exhaust pressure is really, really high resulting in the XS nearly being louder than the TR1.

Probably install that H-pipe right somewhere overhere, where the twin pipes are joined into one on each side.

Subscribe to:

Posts (Atom)